AIRCRAFT CONTROL CABLES

INTRODUCTION :

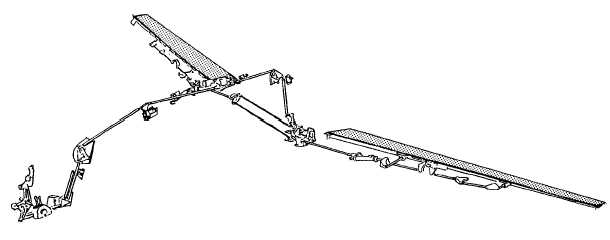

As we know, the pilot of an aircraft needs to control the surfaces that govern the attitude of flight of the aircraft. There are various methods of achieving this i.e. the use of control cables, or control rods , or electrical signals (fly by wire), etc.

Control cables provide a strong, light and flexible method of control. These cables only operate in tension, and can only be used in a pulling direction. However, cables are normally arranged in pairs, that is making a continuous loop, providing a pull in both directions.

CABLE CONSTRUCTION :

The cable is made of galvanized steel and is normally impregnated with a friction preventative lubricant during manufacture. Cable design is based on the number of strands and the number of wires in each strand.

The most common aircraft cables are 7 x 7 and 7 x 19. See figure below for typical examples of cables.

7 x 7 CABLE :

The 7 x 7 cables is of medium flexibility and is used for fairly light application like engine controls and control tabs, where there is not too much load.

7 x 19 CABLE :

The 7 x 19 cables mainly use on primary flight controls where a more flexible cable is required.

CABLE INSPECTION :

For a cable system to operate effectively the cable tension must be correct. Excessive tension imposes an unnecessary loading on the system, whereas a slack cable could cause an ineffective response to a control signal. As cable runs are some times over a large distance it may be necessary to have more then one cable in a run. The method of joining cables together is achieved by using a turn barrel arrangement as shown in figure below.

When adjusting cable control, it is important that the cable end-fittings do not foul the pulley otherwise cable movement will be restricted.

The inspection of aircraft control cables is limited to a visual survey of the cable. Particular attention must be paid to the condition of the cable with emphasis on the surface condition of the cable for corrosion and also for broken strands of wire within the cable construction.

Do you like this post? Please link back to this article by copying one of the codes below.

URL: HTML link code: BB (forum) link code:

0 comments:

Post a Comment